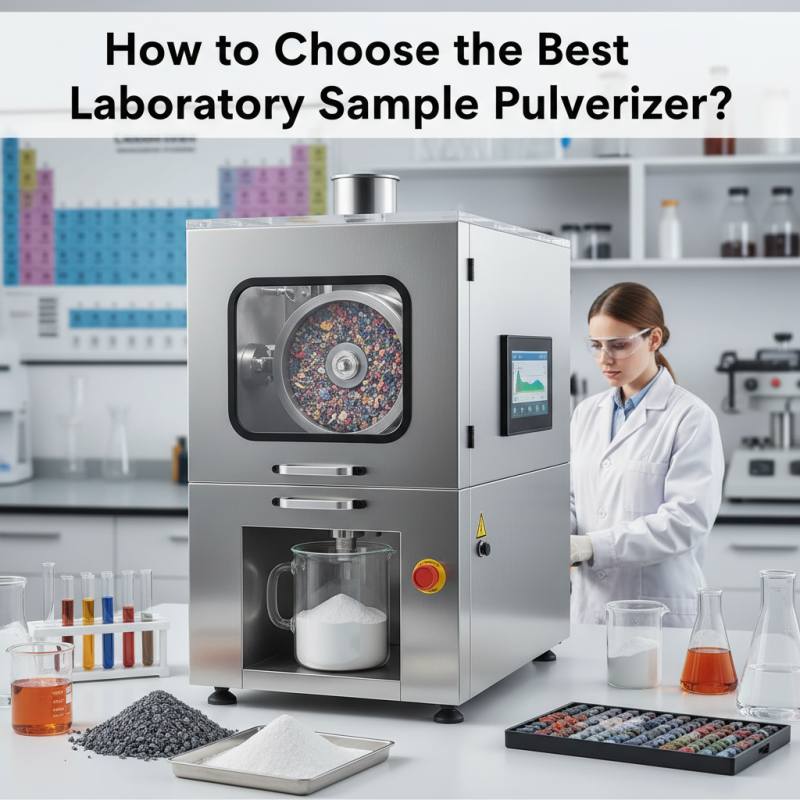

How to Choose the Best Laboratory Sample Pulverizer?

Choosing the right laboratory sample pulverizer is crucial for accurate analysis. Many factors come into play, including material type, particle size, and desired output. Laboratory sample pulverizers vary in design and capabilities, making the selection process a bit overwhelming.

It is essential to consider your specific needs. For example, do you require high throughput or fine particle size? Each laboratory sample pulverizer has strengths and weaknesses. Some may excel in speed, while others might offer precise control over particle size.

Choosing blindly can lead to subpar results. Often, labs overlook the importance of matching the pulverizer to their samples. A pulverizer that works for one material may not be effective for another. Researching, consulting with experts, and understanding your laboratory’s requirements will guide your decision. Take the time to reflect on these factors; it matters in the long run.

Understanding the Purpose of Laboratory Sample Pulverizers

Laboratory sample pulverizers play a crucial role in preparing samples for analysis. They help in reducing the size of materials, making them suitable for various tests. Understanding their purpose is essential. These devices can finely grind solid samples, which is vital in fields like geology, materials science, and pharmaceuticals.

The right pulverizer can improve the quality of your results. Different materials require different grinding methods. For example, brittle materials may need a different approach than ductile ones. It's important to consider how the pulverizer's design affects the end results. Some devices produce heat during grinding, affecting sensitive samples. This is an aspect that cannot be overlooked.

Choosing the right pulverizer can be challenging. Operators often encounter issues with inconsistencies in particle size. This may lead to unreliable test results. Frequent calibration and maintenance are necessary. Over time, one might also notice wear and tear, which impacts performance. Addressing these issues is essential for obtaining accurate and reproducible results. Understanding the purpose of these machines helps in making better choices.

Types of Laboratory Sample Pulverizers and Their Applications

Laboratory sample pulverizers come in various types, each suited for specific applications. Common types include rotary ring pulverizers, ball mills, and hammer mills. Rotary ring pulverizers are great for fine grinding. They provide uniform particle sizes and are excellent for materials like minerals. On the other hand, ball mills are versatile. They can handle both wet and dry materials, making them popular for geological samples. Hammer mills, with their high-speed impact, are effective for brittle and fibrous materials.

Tips: When selecting a pulverizer, consider the material you will grind. Understand its hardness and moisture content. Some materials require special care to avoid contamination. Always think about your sample size. A large sample may not fit in smaller machines.

Another consideration is maintenance. Different pulverizers demand different levels of upkeep. Hammer mills often need frequent cleaning due to their operation method. A simpler design might be easier to maintain but could lack the efficiency of more complex models. It's essential to weigh these aspects based on your laboratory’s needs.

How to Choose the Best Laboratory Sample Pulverizer? - Types of Laboratory Sample Pulverizers and Their Applications

| Pulverizer Type | Application | Advantages | Disadvantages | Sample Size Range |

|---|---|---|---|---|

| Hammer Mill | Hard and brittle materials | High throughput, effective for coarse grinding | Can generate heat, affecting sensitive samples | 1 mm to 10 cm |

| Ball Mill | Minerals, ores, and various powders | Uniform particle size, suitable for fine grinding | Long processing time, requires more power | 100 µm to 10 mm |

| Disc Mill | Grains, legumes, and similar materials | Low dust generation, good for organic samples | Less effective for hard materials | 1 mm to 30 mm |

| Cryogenic Mill | Biological samples and temperature-sensitive materials | Prevents heat generation, preserves sample integrity | Higher operational costs, requires liquid nitrogen | 0.5 mm to 5 mm |

| Rotor Mill | Tough and fibrous materials | Fast grinding, versatile for various materials | Limited to softer samples | 0.5 mm to 30 mm |

Key Features to Consider When Selecting a Pulverizer

Choosing the right laboratory sample pulverizer can be challenging. Several key features help in making an informed decision. One of the most important aspects is the material of the pulverizer. Different materials offer varied durability. Stainless steel is common due to its resistance to corrosion. But is it the best choice for your specific samples?

Another crucial feature is the size of the sample feed. Some pulverizers can handle larger samples, while others are better for small ones. The size impacts your efficiency and workflow. Think about your typical sample size before making a selection. Also, consider the pulverization speed. Faster pulverizers may save time but could affect the sample's quality. It's vital to find a balance between speed and consistency.

Noise levels are often overlooked. Some equipment operates quietly, while others can be quite loud. If working in a shared space, this could be a significant issue. Remember to check the maintenance requirements too. Regular upkeep is necessary for optimal operation. However, not all machines are easy to maintain. Reflect on how much time and resources you can commit to maintaining your pulverizer.

Assessing Sample Size and Material Compatibility for Pulverizers

When choosing a laboratory sample pulverizer, assessing sample size is crucial. A pulverizer should handle the volume efficiently. Small samples may require less powerful machines. However, larger samples call for robust systems. Understanding the optimal sample size helps avoid failures. If the pulverizer is too small, it won't produce desired results.

Material compatibility is another vital factor. Different materials behave uniquely under processing. For instance, hard materials may require stronger blades. Soft materials might not need as much power. It's important to consider the material's characteristics. This can be challenging. You might encounter unexpected interactions during pulverization. A mismatch can lead to poor quality or even equipment damage.

Choosing the right parameters is not always straightforward. There can be discrepancies in performance. Some machines excel with specific materials, while others struggle. Evaluate your needs and conduct small tests first. Observing the pulverization process can reveal what adjustments are necessary. This ensures better outcomes and saves time in the long run.

Budgeting and Cost Considerations for Laboratory Equipment Purchase

When considering laboratory equipment, budgeting is crucial. Many factors influence costs. Features, size, and power consumption can vary widely. A small, basic pulverizer may seem sufficient, but it might not handle larger samples effectively. This leads to additional expenses in the long run. Investing more upfront can save on repairs or replacements later.

Maintenance costs also play a significant role in budgeting. Some models might require frequent servicing. This adds to overall expenses. It's important to evaluate the long-term costs of ownership. Often, choosing a cheaper option leads to higher operational costs. Have a clear picture of your lab’s needs before making a decision.

Balancing quality with budget is challenging. It’s easy to overlook vital features when focused on the price. Look for reviews or testimonials to understand what works best. Sometimes, spending a bit more means accessing innovative features that enhance productivity. This decision might require reflecting on past purchases and their outcomes. Prioritize what aligns with your specific requirements for the best value.

052925 - AI Translation 101 (1).png)

.jpg)